Chemical & Petrochemical

- Share

There are many dangerous and highly flammable chemicals in the chemical and petrochemical industry that can be transported, handled and processed efficiently.

These processes, such as the transfer of chemicals between tank cars and rail cars, filling and mixing in barrels or IBCs, and small operations such as dispensing solvents from safety tanks, human movement, can produce harmful static levels. The most effective static control solution to eliminate the fire and explosion hazards caused by static electricity is to use modern special static control equipment.

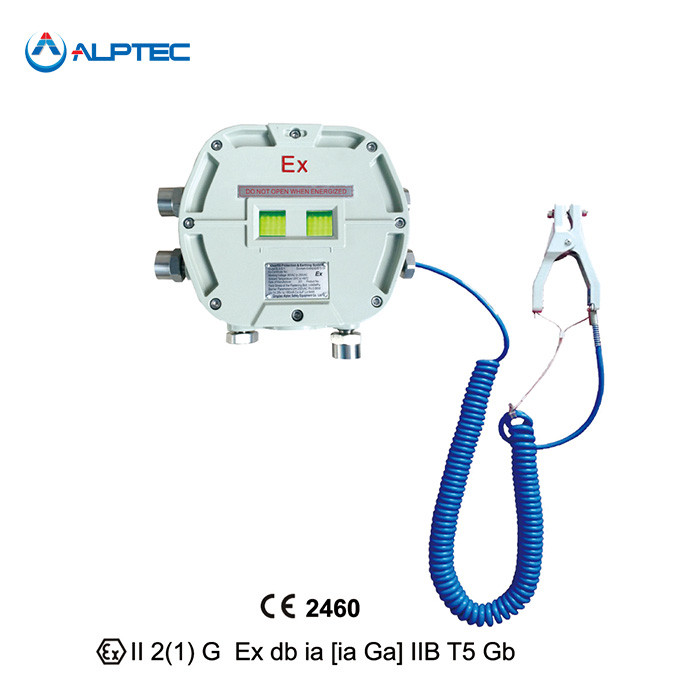

The "Static Grounding Monitoring System" functions as a part of an Overfill Protection & Earthing System. These provide a visual green light indicating a confirmed grounding condition of road tanker vehicles during the transfer of flammable and combustible materials. A red light indicates the absence of dependable grounding. An interlock circuit inside the control panel will prevent pumps and equipment from starting until a satisfactory ground is established. The interlock circuit will also shut off pumps and equipment if the ground is lost during the pumping operation.

The ATEX approved "Static Grounding Reels" have a selfretracting cable drum and an instant locking mechanism to prevent the cable from becoming tangled. The standard S-RL model includes a 7m (23ft.) polyurethane jacketed stainless steel cable. An ATEX approved, heavy duty grounding clamp (with replaceable stainless steel tips) is connected to the cable for a solid connection to the grounding surface. S-RL Reels are also available with 15m (49ft.) and 20m (65ft.) cable lengths.