The ECH PD Flowmeter: A Comprehensive Overview of Its Features and Functionality

- Share

- publisher

- ALPTEC

- Issue Time

- Sep 18,2025

Summary

This precision instrument is engineered for accurate and reliable direct volume measurement of liquids in demanding industrial environments. Its robust design, coupled with high explosion-proof certification, makes it a trusted solution for sectors like petrochemicals, fuel transfer, and other hazardous area applications. This article details the core functionality, technical specifications, and operational features that define the ECH flowmeter.

The ECH PD Flowmeter: A Comprehensive Overview of Its Features and Functionality

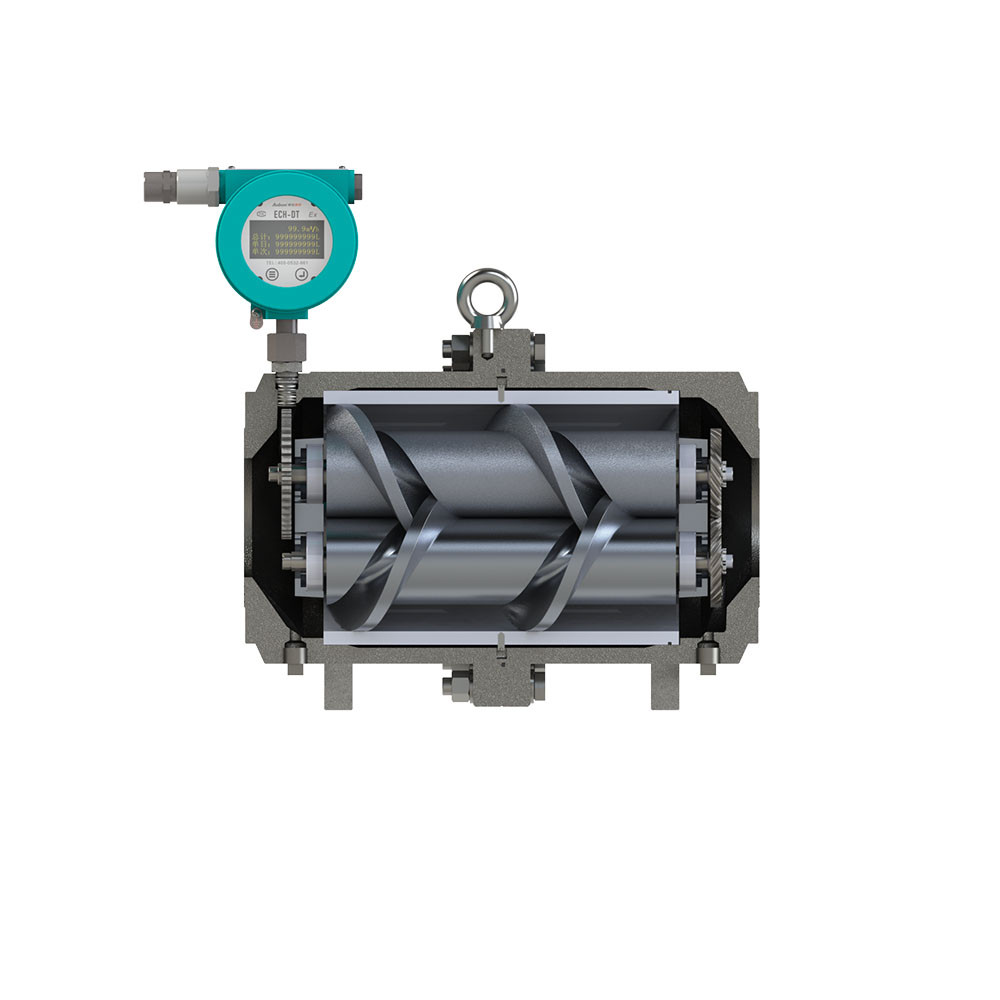

Positive Displacement Technology

Unlike inferred measurement methods, the ECH flowmeter operates on a fundamental mechanical principle. It works by continuously dividing the flowing medium into known, isolated volume segments. These segments are temporarily separated, carried through the meter's chamber, and counted. This process results in a direct volume measurement, ensuring high accuracy without reliance on software-generated calculations or inferences. This method provides exceptional reliability and consistency.

Key Features and Technical Specifications

The ECH flowmeter is built with a focus on precision, durability, and safety. Its key attributes are outlined below.

High Accuracy and Performance

The meter delivers outstanding measurement accuracy across its various models. Its performance is consistent even with variations in fluid viscosity.

• Superior Accuracy: Offers industry-leading precision, with standard accuracy as high as ±0.15% and optional enhanced accuracy of ±0.075% for specific models.

• Excellent Repeatability: Ensures consistent measurement with a repeatability of 0.02%.

• Wide Viscosity Range: Capable of measuring fluids with a viscosity range from 0.2 to 1000 centistokes (cSt).

Robust Construction and Environmental Protection

Designed for harsh conditions, the flowmeter boasts a resilient build.

• IP68 Enclosure Rating: Provides complete protection against dust and long-term immersion in water, ensuring reliability in wet or dirty environments.

• High-Pressure Operation: Can withstand maximum working pressures up to 2.5 MPa at 38°C.

Explosion-Proof Certification and Safety

Safety is paramount for operations in hazardous locations. The ECH flowmeter meets rigorous international standards.

• Explosion-Proof Mark: Certified Ex db IIC T5 Gb.

• Compliance: Meets standards including GB/T 3836.1-2010 and GB/T 3836.2-2021.

• Safe Operation: Suitable for use in Zone 0 areas containing explosive gas mixtures.

The Flow Rate Indicator/Totalizer

The ECH flowmeter system is complemented by a sophisticated digital indicator and totalizer. This unit processes the meter's signals and provides clear data to the operator.

Display and Readout Functions

The display unit offers comprehensive information on the measured flow.

• Total Accumulation: Tracks the cumulative total volume of liquid that has passed through the meter.

• Daily Accumulation: Records the total volume transferred within a 24-hour period.

• Single Transaction Amount: Measures the volume for an individual delivery or batch. This value automatically clears to zero two minutes after oiling stops.

Configuration and Calibration

Authorized personnel can adjust critical parameters using a magnetic wand, maintaining the explosion-proof integrity of the sealed unit.

• K-Factor Adjustment: The meter's calibration factor can be finely tuned based on on-site verification to maintain optimal accuracy.

• Error Correction: The system allows for precise error compensation to ensure long-term measurement precision.

• Data Clearing: The daily and total volume registers can be reset following a secure unlock procedure.

Installation and Operational Safety

Proper installation is critical for achieving the stated accuracy and ensuring safe operation.

re-Installation Requirements

A correct setup protects the meter and the entire system.

• Pipeline Cleanliness: The process pipeline must be clean and free of any foreign matter.

• Use of Ancillary Equipment: A filter must be installed upstream to protect the flowmeter from debris. An air eliminator is also recommended.

• Valving Strategy: Isolation valves should be placed at both ends of the meter, and a bypass section should be installed for maintenance. A flow limiting valve downstream maintains back pressure.

Safety Protocols

The manual emphasizes strict adherence to safety rules, especially in explosion-proof zones.

• Personal Protective Equipment (PPE): Technicians must use safety gear including hard hats, fire-proof clothing, safety goggles, and gloves.

• Non-Sparking Tools: Only non-sparking tools and explosion-proof test equipment shall be used.

• Power and Wiring: Always disconnect power before opening covers. Confirm power supply voltage is correct before energizing.

• Grounding: The product must be reliably grounded with a wire diameter of no less than 4mm².

System Start-Up Procedure

A careful start-up sequence ensures a smooth and safe commissioning process.

1. System Review: Verify all components are installed correctly, valves are closed, and electrical connections are secure.

2. Pressurization: Slowly open the upstream isolation valve to pressurize the system without shock.

3. Purging: Open the downstream valve slightly (10%) to purge air from the system. Do not exceed the meter's flow range.

4. Leak Check: Close the downstream valve and check all connections for leaks.

5. Initiate Flow: Fully open the upstream valve and start the electronic circuits.

6. Initial Run: Let the system run at 20% of its rated capacity for 5 minutes.

7. Full Operation: Adjust the flow control valve to the required operating rate.

Importance of Filtration

Protecting the precision mechanics of the positive displacement flow meter is essential for longevity and accuracy.

• Mandatory Protection: A filter is required upstream to block pipeline scale, welding slag, and other contaminants.

• Mesh Selection: The appropriate filter mesh size depends on the medium (e.g., 60-80 for gasoline, 40-60 for diesel).

• Maintenance: Filters must be cleaned or replaced regularly to prevent clogging, which increases pressure drop and can cause damage.

Conclusion

The ECH PD Flowmeter represents a robust and highly accurate solution for direct volume measurement in challenging industrial settings. Its explosion-proof design, certified for the most hazardous environments, ensures safety and compliance. With its mechanical measurement principle, versatile model range, and intelligent indicator system, the ECH flowmeter delivers reliable performance crucial for custody transfer and process control. Adherence to the detailed installation, safety, and maintenance guidelines manufactured by Qingdao Aubon Instrument Co., Ltd. is key to maximizing the value and service life of this precision instrument.