ALTRON-3000 Batch Controller: A Comprehensive Guide

- Share

- Issue Time

- Jun 17,2025

Summary

The ALTRON-3000 Batch Controller combines precision, safety, and flexibility for industrial loading systems. Its dual-mode operation, robust design, and intuitive interface make it ideal for hazardous environments. For optimal performance, adhere to installation guidelines and leverage its comprehensive alarm system

Introduction

The ALTRON-3000 Batch Controller is a state-of-the-art quantitative loading system designed for industrial applications in petroleum, chemical, and food sectors. Manufactured by Qingdao Alptec Automation Co., Ltd, this controller integrates advanced technology with robust safety features, ensuring precise and secure operations in demanding environments.

Key Features

• Explosion-proof design: Certified as ExdibllBT4Gb (CE20.1420).

• Dual-mode operation: Supports both networked and standalone workflows.

• High-precision control: Achieves 0.3-grade measurement accuracy when paired with primary instruments.

• User-friendly interface: Features an 8-inch color LCD and optional large-screen display.

• IC card integration: Enables secure, self-service loading via encrypted authentication.

Technical Specifications

• 1. Hardware & Performance

| Parameter | Specification |

| Flow signal frequency | 1–10,000 Hz |

| Temperature range | -20°C to +80°C (configurable) |

Power supply | 220V AC ±10%, 50Hz ±2% |

Operating temperature | -40°C to +60°C |

Dimensions | 350mm × 350mm × 200mm (L×W×H) |

Weight | 30 kg |

2. Safety & Compliance

• Anti-static and lightning protection: Three-level safeguards.

• Alarms: Overfill, temperature, flow rate, and grounding detection.

• Valve/pump control: Slow-start and slow-close mechanisms to prevent water hammer.

Operation Modes

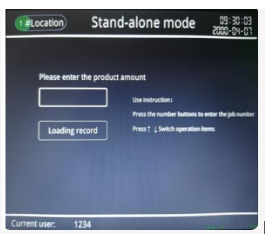

Mode 1: Standalone Mode

1. Enter job number/password via the keyboard.

2. Input the estimated loading amount.

3. Confirm and initiate loading. The system auto-stops when the target is reached.

Mode 1: Networked Mode

1. Swipe IC card or manually enter the bill of lading number.

2. The controller verifies data with the central system.

3. Loading proceeds after validation.

Installation & Maintenance

1. Wiring Guidelines

• Power supply: Use 2-core sheathed wire (ground resistance ≤4Ω).

• Communication: Shielded twisted pair (EIA-485 standard).

• Primary instruments: 3-core shielded wire for valves/temperature sensors.

2. Troubleshooting

| Issue | Solution |

| No display/power failure | Check 220V input and +24V DC terminals |

| Temperature inaccuracy | Verify transmitter wiring and voltage. |

| Valve/pump failure | Inspect for short circuits or debris. |

Safety & Best Practices

• Always ground the system (resistance ≤4Ω).

• Use voltage stabilizers for power fluctuations.

• Regularly inspect wiring and connectors.

• Emergency stop: Press the red button to halt operations instantly.