Tuning Fork Liquid Level Switch Introdcution

- Share

- publisher

- ALPTEC

- Issue Time

- Apr 18,2025

Summary

The Tuning Fork Level Switch is a high reliability control switch specifically designed for level control. The fork has a length of 40mm and can be precisely tuned to measure a minimum liquid density of 0.5g/cm ³.

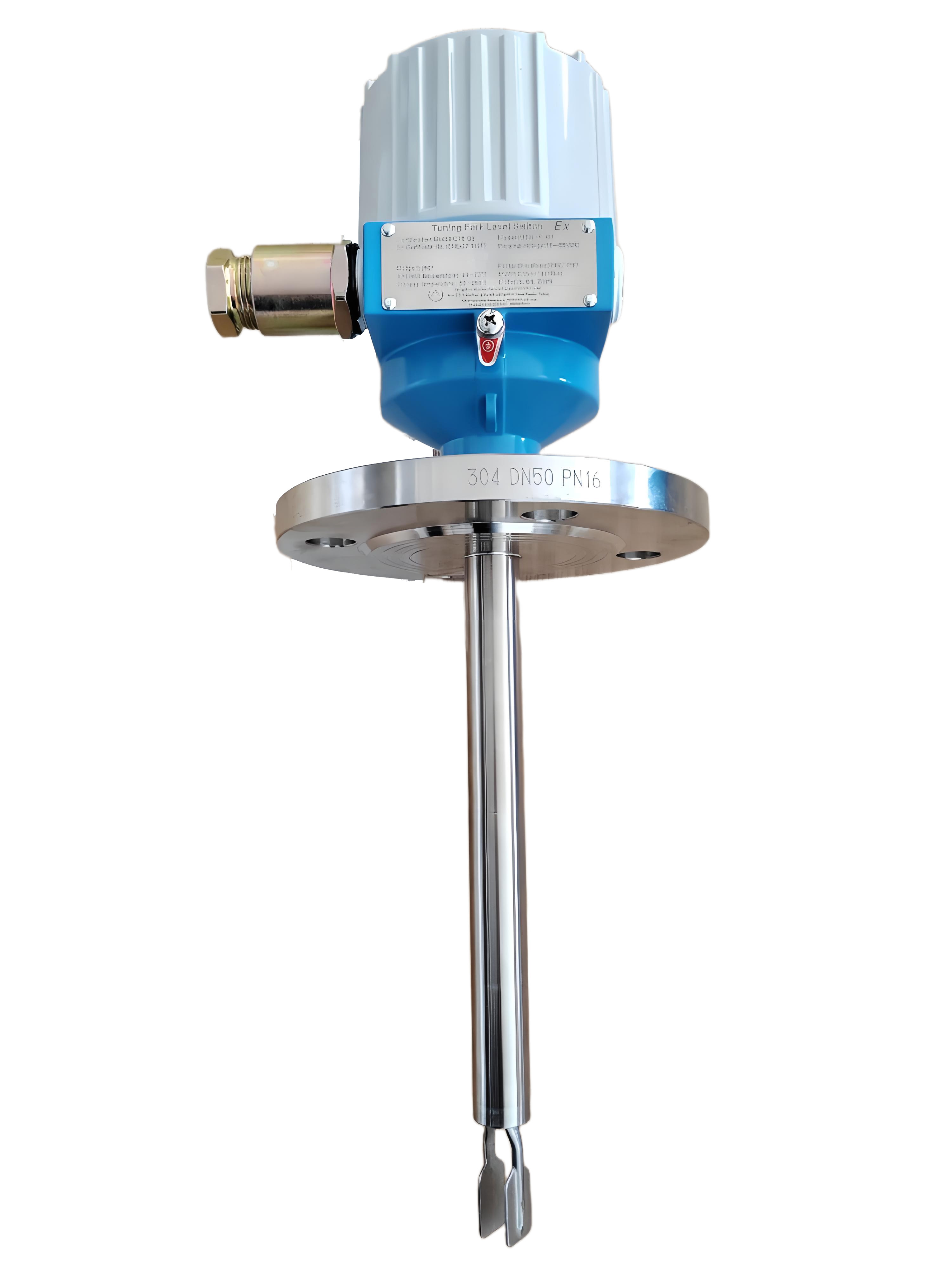

UZK-Y-QJ Tuning Fork Liquid Level Switch

1.Introduction

The Tuning Fork Level Switch is a high reliability control switch specifically designed for level control. The fork has a length of 40mm and can be precisely tuned to measure a minimum liquid density of 0.5g/cm ³.

This Tuning Fork Level Switch has external magnet debugging and frequency display functions.

External magnet debugging function: Simulate alarm signals, which can avoid operating with live covers, allowing you to easily, safely, and quickly complete instrument testing in daily production activities.

Frequency display function: It provides a more intuitive and convenient way to determine whether the device is in working or faulty state, saving you a lot of time in identifying safety hazards. It also comes with a three-color light display function, making it easy to determine the device's working status from a distance.

2. Working principle

The Tuning Fork Level Switch uses piezoelectric components to drive and detect the vibration of the fork body. When the fork comes into contact with the liquid, the resonant frequency of the fork decreases, and the change in fork frequency is directly reflected in the output signal of the piezoelectric detection device. The detection circuit distinguishes and outputs a switch signal through the change in fork frequency.

3. Application

Tuning Fork Liquid Level Switch is specially designed for liquid level control of containers, tanks and various pipelines, and is widely used in water conservancy, chemical industry, environmental protection, food, medicine and other industries.

4. Features

(1) Fork body vibration frequency can be displayed; the stability becomes visible.

(2) Functional testing pen debugging, no need to open the cover.

(3) Three-color light status display, which can remotely determine the working status.

(4) The production process has invention patents which ensures the high reliability.

(5) It has a self-check feature to accurately locate fault.

(6) High temperature resistant design, with a process temperature of up to 280 ℃.

For more information, please contact

QINGDAO ALPTEC SAFETY EQUIPMENT CO., LTD.

Add.: No.13 Hancheng Road, Qingdao Free Trade Zone,

Shandong Province, 266555.P.R. China

Tel: +86(0)532 86761721

Email: catherine@alptec.com