Anti-static measures

- Share

- publisher

- ALPTEC

- Issue Time

- Oct 10,2020

Summary

Anti-static measures and Grounding type.

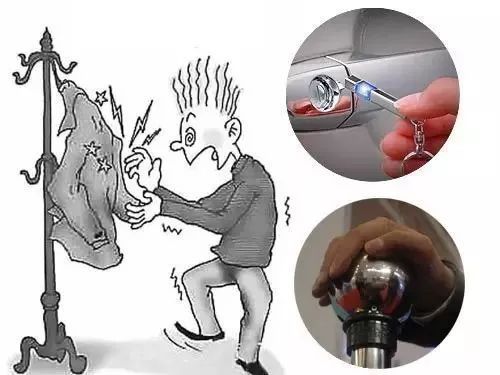

(1) Use conductive materials. Materials

with a resistivity of less than 105Ω·m generally

do not accumulate static electricity.

(2) Reduce frictional resistance, such as

using pipes with a large radius of curvature to limit the flow rate of

electrostatic liquid in the pipe to prevent splashing and impact.

(3) Increasing the environmental humidity

can increase the leakage of static electricity along the surface of the

insulator.

(4) Grounding is an effective way to

eliminate static electricity on the conductor, simple, reliable, and low cost.

Anti-static grounding

Grounding is the simplest and most commonly

used method to eliminate static electricity disasters, and its types include

the following three.

(1) Direct grounding, that is, conducting a

conductive connection between the metal conductor and the ground, so that the

potential of the metal conductor is close to the ground potential.

(2) Indirect grounding, that is, in order

to electrostatically ground the electrostatic conductor and electrostatic

voltage conductor outside the metal conductor, all or part of its surface is

tightly connected with the grounded metal conductor, and this metal is a type

of grounding electrode.

(3) Jump grounding, that is, structurally

fix metal objects through mechanical and chemical methods, so that two or more

mutually insulated metal conductors are electrically connected to establish a

low-impedance path that provides current flow , And then ground a type of

grounding.

Ground object

Usually there are the following types of

grounding objects.

All equipment and pipelines used to

process, store and transport various flammable and explosive liquids,

combustible gases and combustible dust, such as oil tanks, gas storage tanks,

oil transportation pipeline devices, filters, adsorbers, etc., must be

grounded. If the bag filter is made of textile or similar. It is recommended to

use a metal wire to pass through the seam and ground it; if the pipe is made of

non-conductive material, wire a metal wire outside or inside the pipe and

connect the wire to the ground.

For mobile equipment, such as automobile

tankers, train tankers, oil tankers, trolleys, and mobile containers, special

grounding joints such as jaw clamps or bolts should be installed in safe places

to make the mobile equipment well-grounded and prevent the accumulation of

charge on mobile devices. When the tank truck and oil tank truck are in place,

stop the brake and close the circuit. Before opening the tank lid, ground it

first, and at the same time, ground the crane pipe and other movable parts

separately. After the oil filling is completed, remove the oil pipe first, and

after a certain period of time (usually 3min~5min or more), the ground wire can

be removed. A dedicated grounding soft copper wire (or conductive rubber drag

strip) should be installed on the automobile tanker, which shall be firmly

connected to the tanker and hung on the ground to conduct away the static

electricity generated when the automobile is running.