Advantages of Mass Flow Meters in Oil Terminal Handover System

- Share

- publisher

- ALPTEC

- Issue Time

- May 8,2020

Summary

The Coriolis principle Mass Flow Meter can directly measure the mass flow of the fluid in the pipeline, greatly reduce the cost of the oil terminal perfectly solve the existing oil generation problem, and add a high-precision online density measurement function through density calibration.

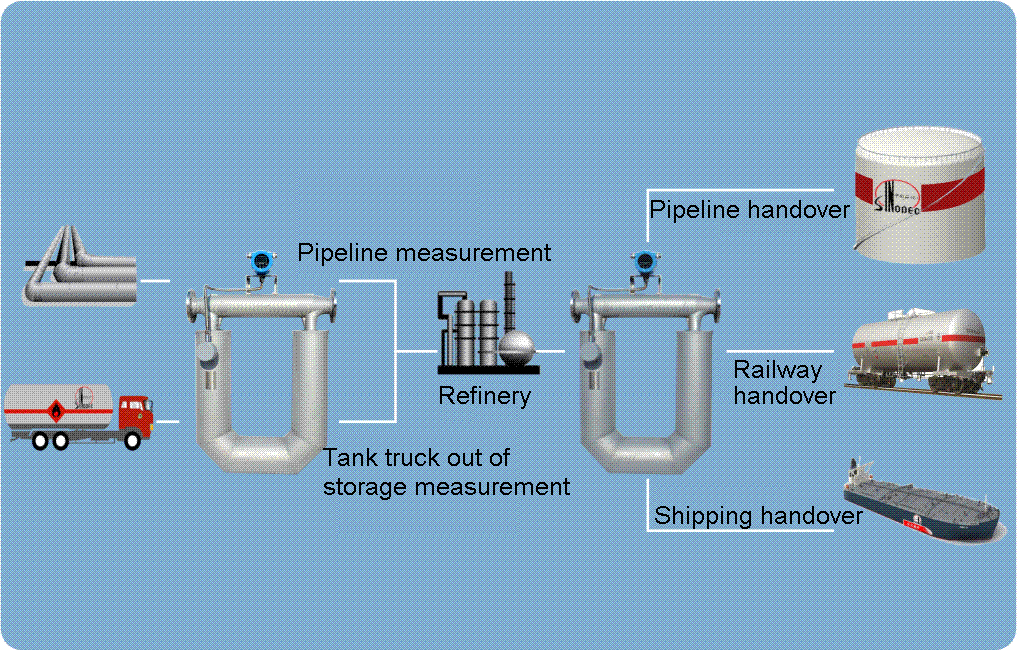

Petroleum is an important energy

resource, which plays an important role in the social life and production. As

an important place for storage and transfer of refined oil, oil depot is a very

important link in the whole refined oil supply system. At present, the Volumetric

Flow Meters is still the main solution in the loading process of oil terminal in

China, and the oil terminal oil depot need to use different fuel delivery

methods according to different customers. The internal gas station

transportation is generally based on V20 and ρ20, and the delivery outside the

station is generally settled by quality. This brings great trouble to the

calculation of various data in the oil depot, such as cumbersome operations and

large errors, etc., and the mass flow meter can perfectly achieve the arbitrary

conversion of quality and V20, saving time,effort and costs.

Do you encounter the following problems:

1. Large workload, low accuracy, and large loss when measuring how much

oil in storage

2. The oil density measurement is troublesome, the workload is large and

unsafe;

3. Both Mass Flow Meters and V20 are required, while the Volumetric Flow

Meters can only measure the volume, so the mass needs to be converted.

The reasons are as bellow:

1.The oil terminal disk storage is settled by quality, but most of the oil

in the oil terminal is a Volumetric Flow Meters. The volume accuracy is 2‰. It needs to be matched with density and

temperature to be converted into quality. Due to the accumulation of errors,

the quality accuracy cannot meet the requirements, the workload is also large,

and the Volumetric Flow Meters needs to be replaced or maintained every six

months to one year;

2. The volumetric flow meter cannot measure the density. The

density of the oil product needs to be measured manually by the tanker truck or

a special density meter is installed. The measurement of the tanker truck is

not traceable and does not meet the safety regulations. And the bottom loading

is not allowed to open the cover sampling, because it would pollute the

environment and doesn’t meet the requirements of relevant national

environmental protection documents, and the cost of separately equipped with a

density meter is higher.

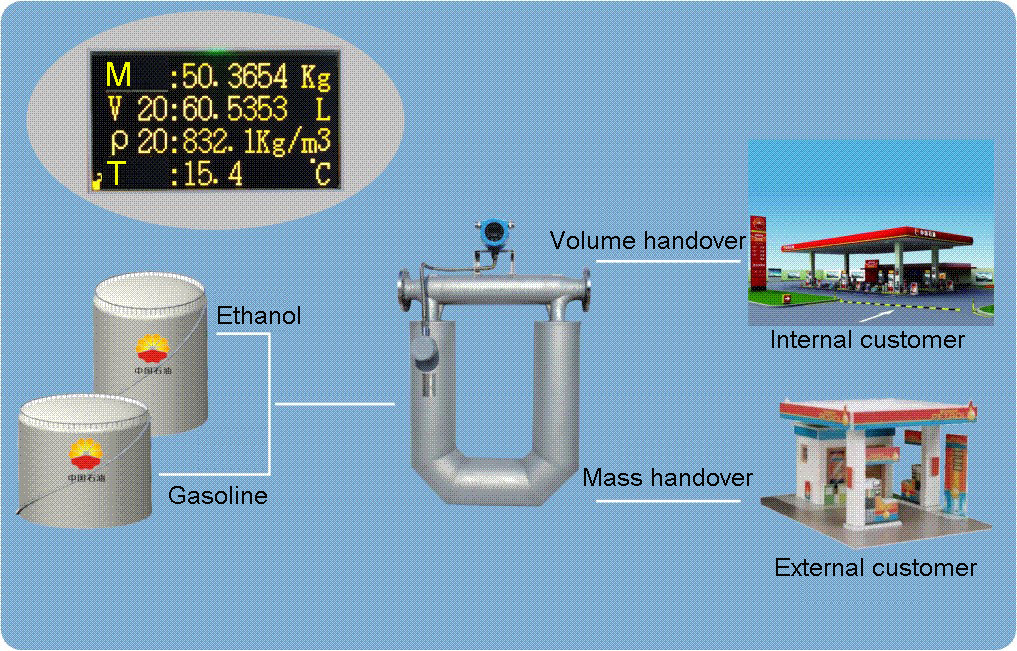

A Mass Flow Meter can solve the above troubles:

The Coriolis principle Mass Flow Meter can directly measure the mass flow of

the fluid in the pipeline, greatly reduce the cost of the oil terminal,

perfectly solve the existing oil generation problem, and add a high-precision

online density measurement function through density calibration (The accuracy

of density measurement is better than ± 0.0005g / cm³), which can realize

multi-use of one machine:

1.Solve the digital quality inventory of outbound and inbound

|

Item |

Existing measurement model |

New method |

||

|

Volumetric Flow Meter |

Density Measurement |

Thermometer |

Add Value Mass Flow Meter |

|

|

V20 |

Error is 0.2% |

/ |

/ |

Error is 0.15% |

|

Real-time temperature |

/ |

/ |

Error is±0.5℃ |

Error is±0.2℃ |

|

ρ20 |

/ |

Manual measurement needs to open the cover which will cause air

pollution and time-consuming and laborious, the error is±0.001g/ cm³ |

/ |

Direct measurement, the error is±0.0005g/ cm³ |

|

Mass |

Through volume, density and temperature conversion, the error is ±0.3% |

Direct measurement, the error is±0.1% |

||

|

Cost |

They need to be maintained every six months. |

Lifetime is over 10 years |

||

The followings are photos and data records of the application of Mass Flowmeter

in a Sinopec oil terminal to achieve mass and V20 oil delivery.

|

Oil terminal

Flowmeter calibration record |

||||||||||||

|

Variety |

Flow Meter Terminates Reading (L) |

Flow Meter Mass (Kg) |

Standard Density (Kg/m³) |

Standard density measured manually (Kg/m³) |

Density Error (‰) |

Standard Tank Oil Temperature Tb |

Flow Meter Measures Temperature Ta |

Temperature Error (Ta-Tb) |

Standard Tank Real Volume (L) |

Volume Error (‰) |

Actual Mass (Kg) |

Mass Error (‰) |

|

92# |

1996.4 |

1473.4 |

741.5 |

741.1 |

0.4 |

23.6 |

24.2 |

0.6 |

1997.8 |

-0.7 |

1471.7 |

1.2 |

|

92# |

2002 |

1476 |

741.5 |

741.2 |

0.3 |

26.4 |

26.2 |

-0.2 |

2003.7 |

-0.8 |

1474.8 |

0.8 |

|

92# |

1994 |

1465.5 |

741.6 |

741.2 |

0.4 |

27.6 |

27.8 |

0.2 |

1995.5 |

-0.8 |

1463.6 |

1.3 |

|

92# |

2003 |

1471 |

741.6 |

741.3 |

0.3 |

28.1 |

27.8 |

-0.3 |

2005 |

-1 |

1470.5 |

0.3 |

|

95# |

2004.1 |

1485.5 |

748.7 |

749 |

-0.3 |

28.1 |

28 |

-0.1 |

2007.7 |

-1.8 |

1486.1 |

-0.6 |

|

95# |

1996 |

1482 |

748.6 |

748.5 |

0.1 |

27.2 |

26.9 |

-0.3 |

1997.1 |

-1 |

1480.3 |

1.1 |

According to the data, it can be seen that the volume error of Mass Flowmeter

is within ± 0.2%, the density error is within ± 0.0005g / cm³, and the mass

error is within ± 0.15%. Both mass and V20 can be transferred at the same time,

and it can replace the manual measurement of density.

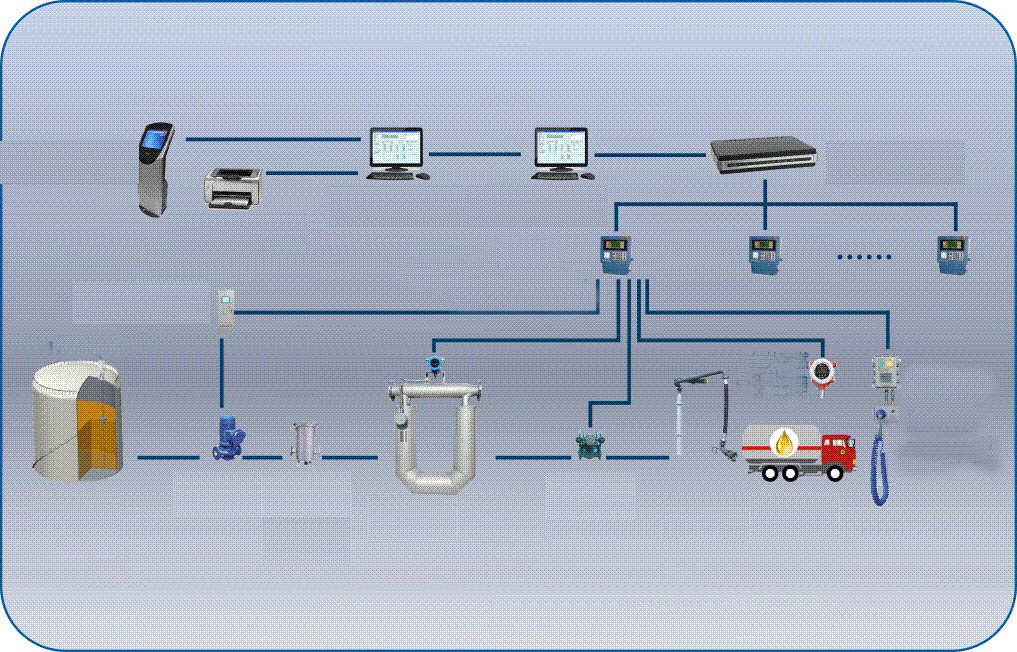

Benefit

1. A high-precision Mass Flow Meter can replace the functions of existing

measuring instruments (Volumetric Flow Meters, Density Meter,

Thermometer), which greatly reduces the cost of equipment;

2. The data can be concentrated and displayed on the transmitter (mass,

volume, V20, ρ20), which is convenient for the measurement personnel to view and

operate and reduce the measurement time;

3. It can be uploaded to the database (data can be stored and traceable),

and the degree of data visualization is high;

4. There are no moving parts inside the Mass Flow Meter, no regular

maintenance is needed, and the service life can reach more than ten years,

which is much higher than the Volumetric Flow Meters in three to five years,

which can greatly reduce the equipment maintenance cost.

The Mass Flow Meter can meet the needs of customer V20 and quality

handover and quality depots in oil terminals.